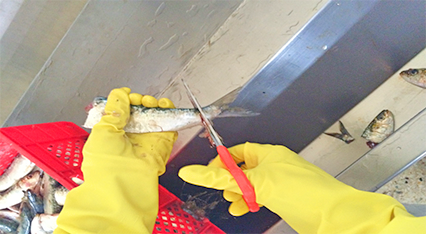

With regard to the company’s philosophy, the final product is at the center of our concerns: MAPI’s fish-processing method consists of four main delicate steps aiming at conserving all the flavors and keeping the product at highest quality:

STEP 1 :

Fish head and tail are removed. Fish beheading has to be always from the dorsal side forward to the pelvic fins. This way, all the viscera are eliminated and fish quality and presentation are not affected.

STEP 2 :

In the same operation, viscera are delicately pulled out

STEP 3 :

Once fish body is ready, it is placed in brine ponds. Again, it is reminded to all fish processing workers at MAPI that it is strictly forbidden to cut fish from belly forward as it damages the fish and seriously affects the product quality.

Human Resource Development Programs :

Our clients can be sure of one thing: their product is in clean hands. Workers go through various training sessions about hygiene:

Proper clothing/equipment:

Sanitary regulations:

Fish - processing :

Proper cutting :

Crates disposal :

Cooking Grill-filling :

Pre-cooked mackerel ‘fillet’ selection :

Can-filling :

Training programs include a combination of presentations and workshops allowing trainees to practice their learning. At the end of sessions, employees go through a final test assessing their eligibility to an Award Certificate delivered by MAPI HR team.